Difference Between Hot Rolled And Cold Rolled Aluminum . Cold rolling hardens and strengthens the aluminum by changing its microstructure,. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and. Rolling this aluminum flat can be done in two different ways: If they do not heat the aluminum before rolling, the aluminum will be cold worked. Hot rolling or cold rolling. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Hot rolling or hot working is the standard. Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. As for cold rolled aluminum, after the. In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance.

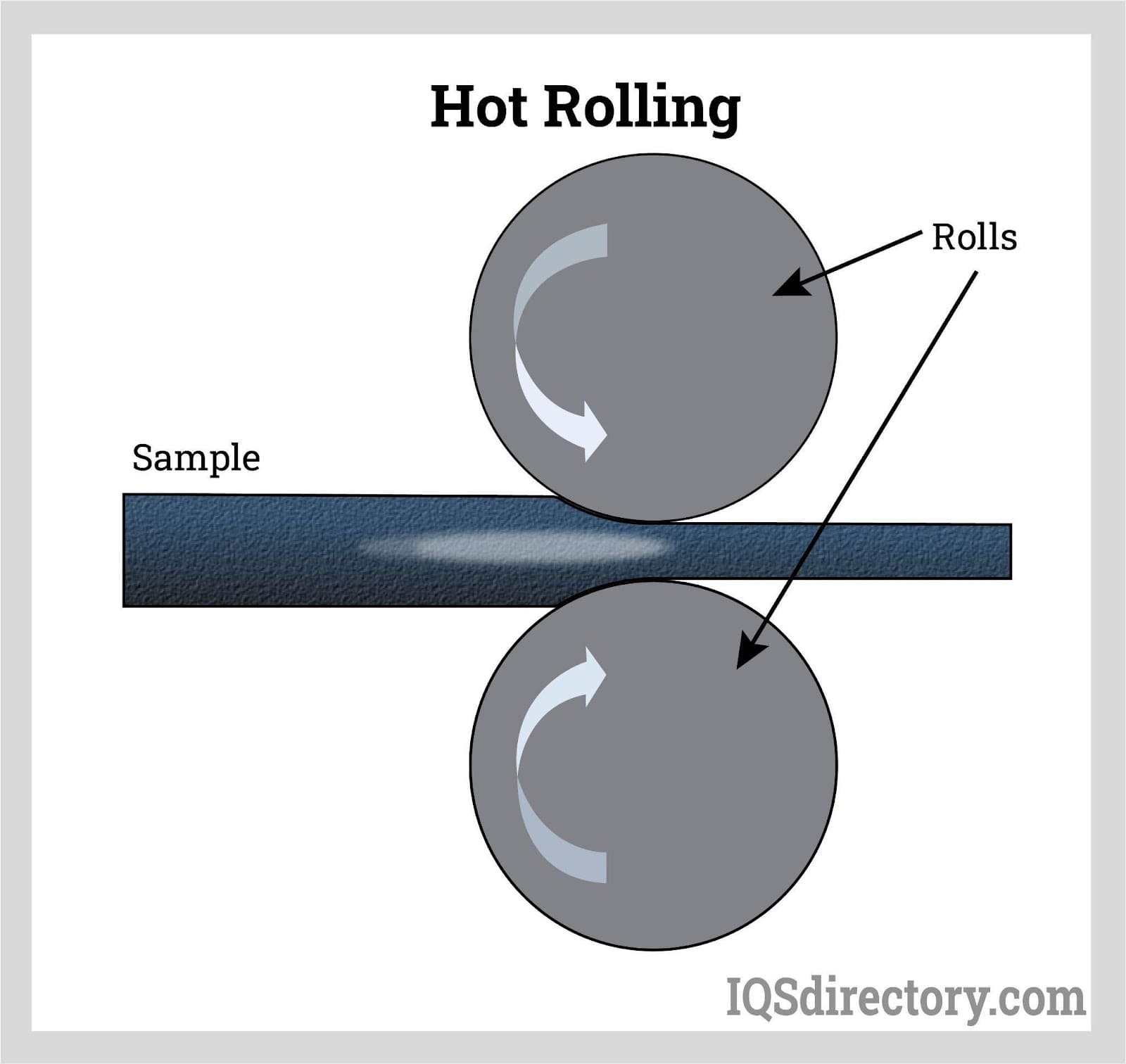

from www.iqsdirectory.com

Cold rolling hardens and strengthens the aluminum by changing its microstructure,. Hot rolling or cold rolling. Hot rolling or hot working is the standard. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Rolling this aluminum flat can be done in two different ways: Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and. If they do not heat the aluminum before rolling, the aluminum will be cold worked. As for cold rolled aluminum, after the.

Aluminum Coil Types, Grades, Applications & Advantages

Difference Between Hot Rolled And Cold Rolled Aluminum The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Cold rolling hardens and strengthens the aluminum by changing its microstructure,. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and. Hot rolling or cold rolling. Rolling this aluminum flat can be done in two different ways: As for cold rolled aluminum, after the. In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance. Hot rolling or hot working is the standard. If they do not heat the aluminum before rolling, the aluminum will be cold worked.

From blog.thepipingmart.com

Hot Rolling vs Cold Rolling What's the Difference? Difference Between Hot Rolled And Cold Rolled Aluminum If they do not heat the aluminum before rolling, the aluminum will be cold worked. Cold rolling hardens and strengthens the aluminum by changing its microstructure,. In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so. Difference Between Hot Rolled And Cold Rolled Aluminum.

From hkfabrication.com

Hot Rolled vs. Cold Rolled Steel A Comparison Guide Difference Between Hot Rolled And Cold Rolled Aluminum As for cold rolled aluminum, after the. Rolling this aluminum flat can be done in two different ways: Cold rolling hardens and strengthens the aluminum by changing its microstructure,. Hot rolling or hot working is the standard. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and. Hot rolled material means. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.haomei-aluminum.com

The difference between hot rolled aluminum sheet and cold rolled Difference Between Hot Rolled And Cold Rolled Aluminum As for cold rolled aluminum, after the. In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance. Cold rolling hardens and strengthens the aluminum by changing its microstructure,. Hot rolling or cold rolling. If they do not heat the aluminum before rolling, the aluminum will be cold worked. Hot rolling. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.iqsdirectory.com

Aluminum Coil Types, Grades, Applications & Advantages Difference Between Hot Rolled And Cold Rolled Aluminum If they do not heat the aluminum before rolling, the aluminum will be cold worked. Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet. Difference Between Hot Rolled And Cold Rolled Aluminum.

From eziil.com

What is the Difference Between Hot Rolled (HR) & Cold Rolled (CR) Steel? Difference Between Hot Rolled And Cold Rolled Aluminum Cold rolling hardens and strengthens the aluminum by changing its microstructure,. Hot rolling or cold rolling. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Hot rolling or hot working is the standard. Rolling this aluminum flat can be done in. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.rmtus.com

Cold Rolled Vs. Hot Rolled Steel RMT Revolution Machine Tools™ Difference Between Hot Rolled And Cold Rolled Aluminum The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. If they do not heat the aluminum before rolling, the aluminum will be cold worked. Rolling this aluminum flat can be done in two different ways: Hot rolling or hot working is. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.reliance-foundry.com

Hot Rolled vs Cold Rolled Steel Metal Casting Blog Difference Between Hot Rolled And Cold Rolled Aluminum In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance. Rolling this aluminum flat can be done in two different ways: Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. Hot rolling or. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.bushwickmetals.com

Cold Vs HotRolled Steel The Important Differences Explained Difference Between Hot Rolled And Cold Rolled Aluminum The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. If they do not heat the aluminum before rolling, the aluminum will be. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.mt-aluminum.com

Difference between Cold Rolled Aluminum and Hot Rolled Aluminum Difference Between Hot Rolled And Cold Rolled Aluminum In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance. As for cold rolled aluminum, after the. Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. If they do not heat the aluminum. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.youtube.com

What’s the difference between hot and cold rolling YouTube Difference Between Hot Rolled And Cold Rolled Aluminum Rolling this aluminum flat can be done in two different ways: Cold rolling hardens and strengthens the aluminum by changing its microstructure,. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and. If they do not heat the aluminum before rolling, the aluminum will be cold worked. The cold rolling aluminum. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.tbkmetal.com

Difference Between Hot Rolled & Cold Rolled Stainless Steel Sheets? Difference Between Hot Rolled And Cold Rolled Aluminum Cold rolling hardens and strengthens the aluminum by changing its microstructure,. As for cold rolled aluminum, after the. If they do not heat the aluminum before rolling, the aluminum will be cold worked. Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. The. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.southernfabsales.com

The Difference Between Hot Rolled & Cold Rolled Steel Difference Between Hot Rolled And Cold Rolled Aluminum Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. If they do not heat the. Difference Between Hot Rolled And Cold Rolled Aluminum.

From blog.thepipingmart.com

Hot Rolled Steel vs Cold Rolled Steel What's the Difference Difference Between Hot Rolled And Cold Rolled Aluminum Hot rolling or cold rolling. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and. Cold rolling hardens and strengthens the aluminum by changing its microstructure,. The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material,. Difference Between Hot Rolled And Cold Rolled Aluminum.

From reganindustrial.com

What is the Difference between Hot Rolled and Cold Rolled Steel? Difference Between Hot Rolled And Cold Rolled Aluminum In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance. Hot rolling or cold rolling. If they do not heat the aluminum before rolling, the aluminum will be cold worked. As for cold rolled aluminum, after the. Cold rolling hardens and strengthens the aluminum by changing its microstructure,. Hot rolling. Difference Between Hot Rolled And Cold Rolled Aluminum.

From pediaa.com

Difference Between Hot Rolled and Cold Rolled Steel Definition Difference Between Hot Rolled And Cold Rolled Aluminum The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. In the world of aluminum sheets,. Difference Between Hot Rolled And Cold Rolled Aluminum.

From china-maching.com

Hot Rolled vs Cold Rolled Steel Understanding the Differences ETCN Difference Between Hot Rolled And Cold Rolled Aluminum Hot rolling or cold rolling. Rolling this aluminum flat can be done in two different ways: The cold rolling aluminum sheet is with poor mechanical properties and high hardness, so the cold rolling aluminum sheet is commonly used for mould material, and hot rolled. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish,. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.sabasteelng.com

Difference between hot rolled steel and cold rolled steel? Difference Between Hot Rolled And Cold Rolled Aluminum Hot rolled material means the aluminum ingot is smelted and cast into a slab, the milling surface is uniformly annealed, and hot rolled into a strip. Hot rolling or cold rolling. Hot rolling or hot working is the standard. In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance. Rolling. Difference Between Hot Rolled And Cold Rolled Aluminum.

From www.mt-aluminum.com

Difference between Cold Rolled Aluminum and Hot Rolled Aluminum Difference Between Hot Rolled And Cold Rolled Aluminum In the world of aluminum sheets, the choice between cold rolling and hot rolling is about achieving the right balance. The primary differences between hot rolled and cold rolled aluminum sheets lie in their surface finish, grain structure, and. If they do not heat the aluminum before rolling, the aluminum will be cold worked. Rolling this aluminum flat can be. Difference Between Hot Rolled And Cold Rolled Aluminum.